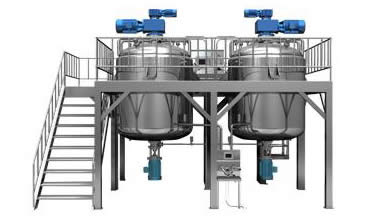

According to the requirements of manufacturing method of ointment and cream products, advanced processing technology from abroad is introduced to specially design bottom homogenizing vacuum emulsifier equipment. As a result this machine can meet technological requirements of ointment manufacturing and emulsifying of cosmetics, medicine and others products. This product is composed of vacuum emulsifying and agitating tank, oil phase boiler, water phase boiler, vacuum pump, hydraulic system, automatic feeding system, electric control system and other devices. In general, this product has simple operation, stable homogenizing performance, high production efficiency and reasonable structure.

Detailed Specifications| Model | Homogenizing blender | Slow speed blender | Vacuum pump | Hydraulic system | Oil and water boiler | Total power | |||

| Power | Speed | Power | Speed | Power | Speed | ||||

| FYZRJ-1000L | 15 kW | 0 ~ 3500 rpm | 5.5 kW | 0 ~ 40 rpm | 4 kW | Naught | 1.5 kW | 0 ~ 960 rpm | 29 kW |

| FYZRJ-1500L | 18.5 kW | 0 ~ 3500 rpm | 7.5 kW | 0 ~ 40 rpm | 7.5 kW | Naught | 2.2 kW | 0 ~ 960 rpm | 32 kW |

| FYZRJ-2000L | 22 kW | 0 ~ 3500 rpm | 7.5 kW | 0 ~ 40 rpm | 7.5 kW | Naught | 2.2 kW | 0 ~ 960 rpm | 35 kW |

| FYZRJ-3000L | 22 kW | 0 ~ 3500 rpm | 7.5 kW | 0 ~ 40 rpm | 7.5 kW | Naught | 2.2 kW | 0 ~ 960 rpm | 35 kW |

| FYZRJ-5000L | 30 kW | 0 ~ 3500 rpm | 7.5 kW | 0 ~ 40 rpm | 7.5 kW | Naught | 2.2 kW | 0 ~ 960 rpm | 45 kW |

Bottom homogenizing vacuum emulsifier equipment has high automatic degree and reverse slow speed scraping agitating. Clinging to the boiler wall and bottom, special scraping agitator has rotation speed of 0~40 rpm frequency conversion. At the same, high speed homogenizing head at the bottom carries out dispersion and emulsification through high speed rotation of 0~3500 rpm frequency conversion. Built-in vacuum pump is equipped to suck material effectively, thus avoiding dust and bubbles after high speed agitating. Through CIP cleaning system, it is very convenient to clean. For vessel, spare parts which may come into contact with materials are made of SUSL 316L stainless steel. The interior surface is treated by sanitary level mirror polishing. Last but not least, bottom homogenizing vacuum emulsifier equipment is manufactured in line with GMP requirements.

As a specialized bottom homogenizing vacuum emulsifier equipment manufacturer and supplier in China, we also offer fully automatic capsule filling machine, automatic tube filling and sealing machine, medical high purity nitrogen generator and so on.